Consumer Products

Engineered noise reduction solutions that deliver exceptional performance, quieter

operation and improved durability for consumer electronics, appliances, and more.

Contact Us Today.

Your inquiry has been received. A DTI Representative will contact you as soon as possible.

For immediate assistance, please call us at 574.258.7916.

DTI HomeEngineered noise reduction solutions that deliver exceptional performance, quieter

operation and improved durability for consumer electronics, appliances, and more.

Our damping systems strengthen product structures without modification of the structure itself, resulting in more durable products.

DTI's composite materials knowledge and extensive engineering experience allows designers to create innovate and high-performing products.

Quieter, smooth-running products create better customer experiences for today's consumer, spurring word-of-mouth and repeat sales.

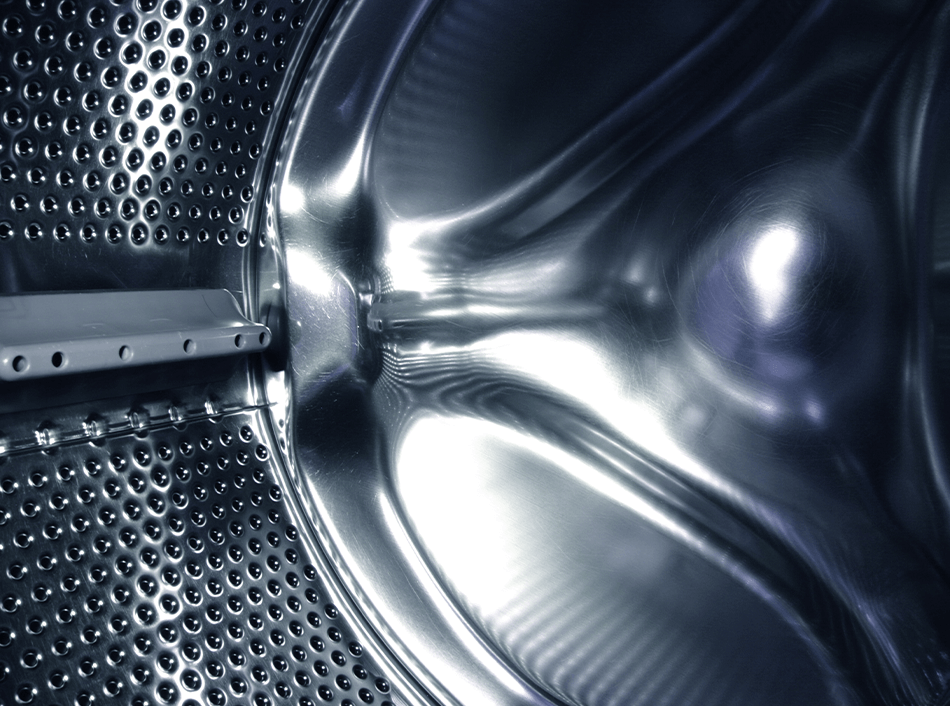

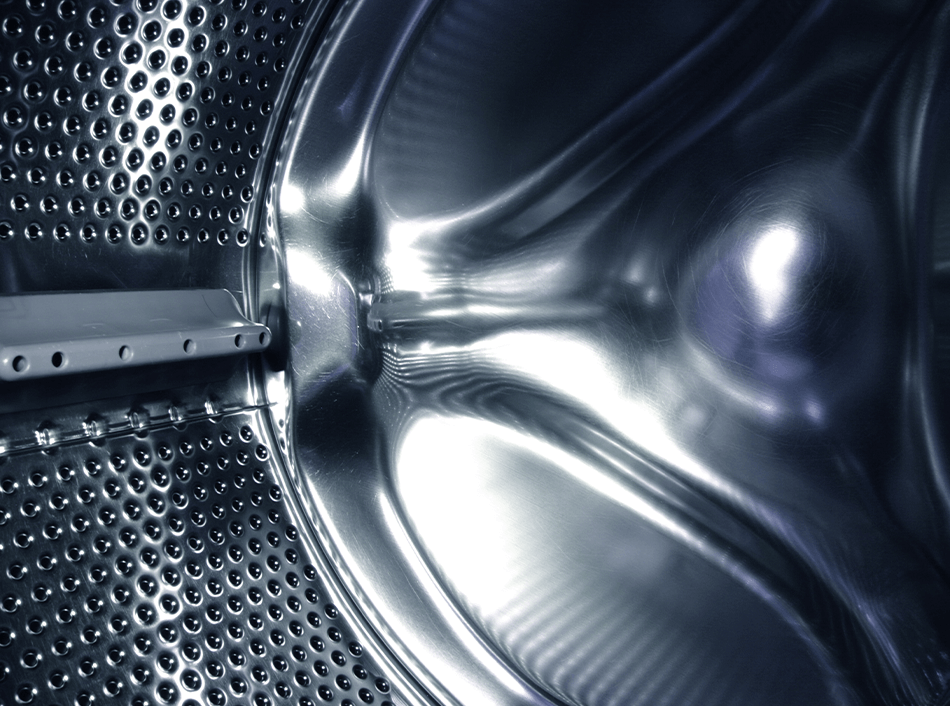

Consumer products such as washers, dryers, dishwashers, vacuum cleaners, lawnmowers, and air conditioning units exhibit unwanted noise and vibration. In these scenarios, particular product must be analyzed to determine the nature of the unwanted noise and vibration.

This typically involves harvesting data via techniques such as acoustic intensity measurements to identity sound pressure level “hot spots”, operating acceleration measurements, and sound pressure measurements. If peaks in the frequency domain are identified in the sound pressure level (SPL) data, and those peaks correlate to peaks in the operating acceleration data (acquired about the structure), then the unwanted noise is due to cyclic forced-vibration effects – from resonance response contributors, or both. If frequency response function (FRF) measurements are acquired on the structure and peaks in the FRFs correlate to peaks identified in the operating data, then the noise and vibration is aggravated by resonance response of the structure.

For situations like this, no countermeasure is more effective for resonance response than damping.

In order to develop an effective solution, it is necessary to understand the particular structural dynamics. If there is a resonance of the structure that correlates to the peak acceleration levels observed during use of the article and also to peak sound pressure levels, then it is very likely that resonance response is contributing to the detrimental behavior. At that point, modal analysis can be performed on the article or structure to define the mode shapes of vibration. With the modal analysis data and FRFs, representative models of the structure can be created and countermeasures can be developed.

Depending on the nature of the resonance issue, a Stand-Off or Constrained Layer Damping System may be appropriate, particularly if the structure is “panel-like” and if multiple resonances contribute to the noise and vibration. If a single resonance is aggravating the noise and vibration profile, then a Tuned Mass Damper (TMD) can be very effective.

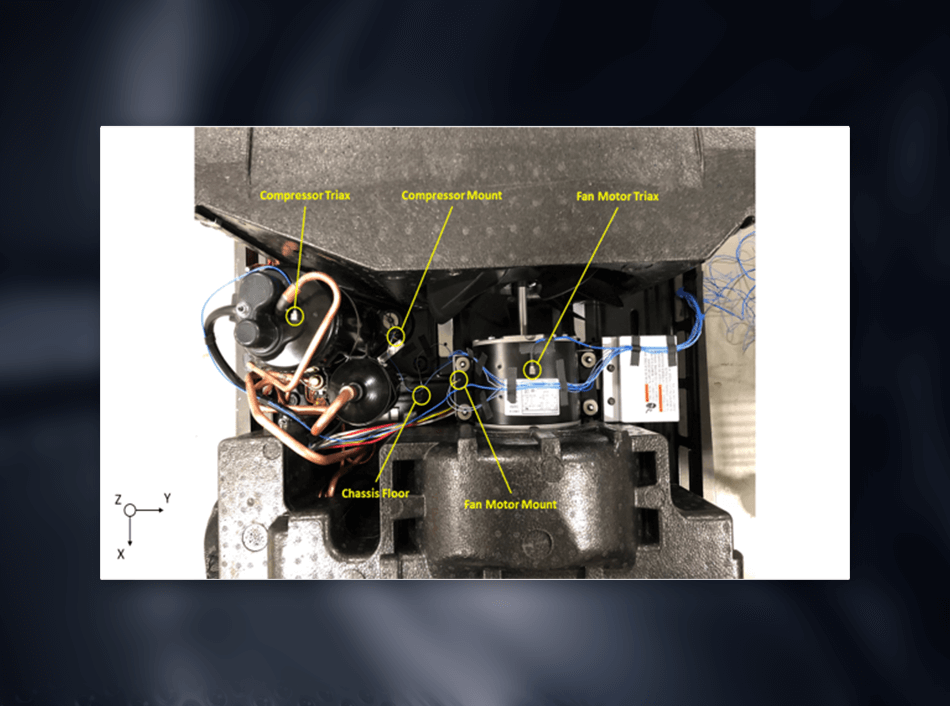

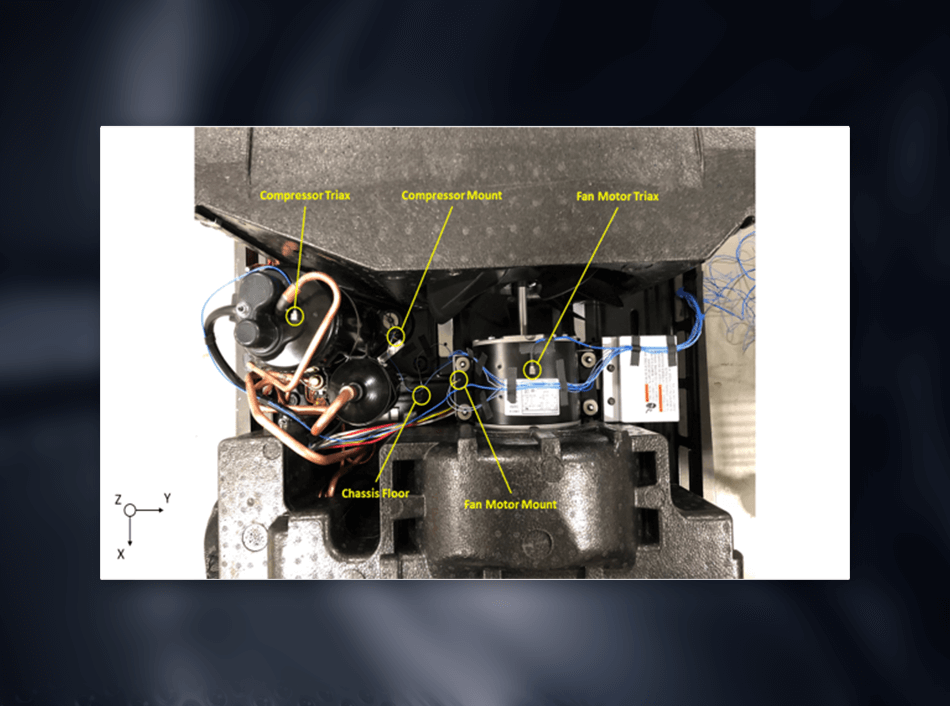

If unwanted vibration, even if due to resonance response, is caused by on-board sources such as a compressor or other motor, often an improved isolation system countermeasure can be very effective. The isolation system de-couples the forcing function from the structure, such that excitation is diminished and response (either forced-vibration or resonance) is diminished accordingly.

Depending on the nature of the noise issue and the frequency content, a decoupled-mass acoustic barrier can be a very appropriate countermeasure. A Tuned Vibration Absorber (TVA) may be appropriate for forced-vibration at a single frequency, especially those from cyclic inputs such as motors and compressors.

Often with consumer products, selection of a solution is dominated by cost considerations.

DTI develops very application-specific countermeasures that depend on detailed analysis of the structure. Depending on the nature of the noise and vibration issue, the appropriate countermeasure can be selected and designed specifically for that application.

DTI has a fully staffed experimental test lab for harvesting experimental data on consumer products. DTI also has extensive FEA and SEA modeling capability, which is fueled by the experimental test lab. DTI uses these measurement and analysis tools to formulate the best and most cost-effective solution. Without thorough analysis, it is almost impossible to bring about a good solution to many consumer product applications.